ONLINE CONFIGURATOR CONFIGURATOR - ARMARiO

ARMARiO STANDS FOR SPEED IN CUSTOMIZED, INDIVIDUAL CONTROL CABINET CONSTRUCTION.

The ARMARiO control cabinet configurator offers uncompromisingly fast planning and production of individual control cabinets. You can configure a simple control cabinet in just 3 minutes. Production begins immediately after receipt of the order. The advantage for you: The control cabinet is delivered completely according to your specifications with all holes and recesses. This saves you time-consuming rework and allows you to start assembling your intended add-on components straight away.

ARMARiO - Save time and costs!

START NEW CONFIGURATION

Time saving

Cost savings

Optimal passport size

We also manufacture all control cabinets stainless steel.

READY TO INSTALL CONTROL CABINETS.

Congratulations - the fact that you're taking the time to read this brochure now makes you a winner. These few minutes will save your company days of planning and rework.

We have put together this brochure to show you how you can get the perfect control cabinet in just a few minutes. This saves you a lot of time and gives you the optimal solution for your packaging machine. Using customer results, you will experience this process in a real and understandable way.

JUST 4 STEPS TO THE PERFECT CONTROL CABINET.

1 variant and dimension

Alle Gehäuse werden millimetergenau skaliert und passen somit in jede Lücke.

All housings are scaled to the millimeter and therefore fit into any gap.

Choose a suitable variant for your control cabinet or terminal box from the models. Define the type of door and the hinge side. Then enter the desired dimensions. All models are scaled to the millimeter and therefore fit exactly into every system module.

2 hole patterns

You will never have to edit a control cabinet with a drill again.

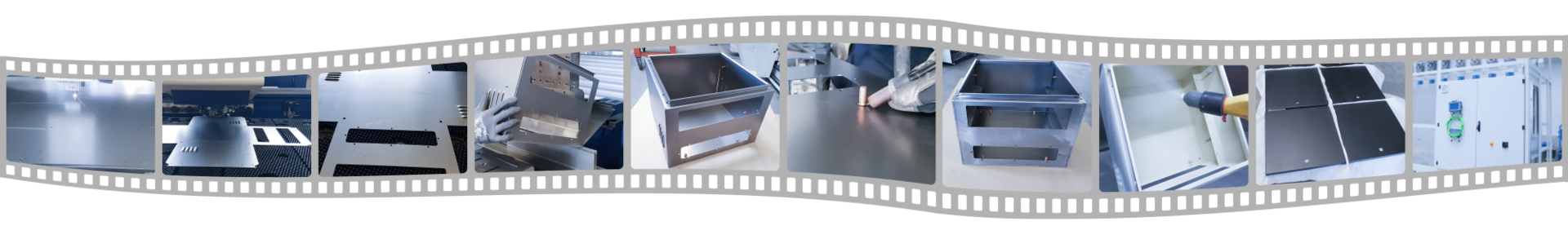

Generate every conceivable hole pattern by dragging and dropping the prefabricated components. The configurator pays direct attention to plausibility, checks for collisions and displays them if necessary. The digital twin of the control cabinet ensures functionality and is the basis for a standard-compliant design.

3 Material and color

Sie sparen sich in jedem Fall den Vorgang des Umlackierens.

In any case, you save yourself the repainting process.

Just one click decides whether your control cabinet is made of sheet steel or stainless steel. Choose the color and surface texture freely according to your taste, the CI of your company or the color request of your customer. Each control cabinet is produced directly in your desired color.

4 Place order

10 days of production time for an individual control cabinet housing is unique in the industry.

Not only can you design, but you can also place orders directly online, 24/7 from anywhere in the world. The data is transmitted directly to our production, which guarantees a short production time. Thanks to the new B2B online ordering process, you can also send your order request to a colleague, e.g. B. forward in purchasing.

CASE STUDIES

Hugo Beck Maschinenbau GmbH & Co. KG

“This is the easiest thing in the world for me. As easy as buying a contactor.”

Hugo Beck Maschinenbau GmbH & Co. KG, Dettingen, Gerhard Fink

Initial situation:

Hugo Beck Maschinenbau is a specialist in horizontal flowpack, film and paper packaging machines. In the past, Hugo Beck was used to buying standard control cabinets and drilling holes himself. To avoid time-consuming rework, internal standard cabinets are already manufactured. Unfortunately, standard cabinets are not suitable in all cases, even if they are refinished.

Challenge:

The control cabinet should be very small. At the same time, the housing also has to be very deep because there is a frequency converter in the control. There are almost no standard solutions for this. Deviations from the internal standard housings always require a great deal of effort in coordination and production. A time and cost saving solution was sought. Time-consuming follow-up work should be avoided. A special design from the previous supplier required separate drawings and a major coordination process. This process costs a lot of time and money. After many drawings and experiments, Hugo Beck became aware of the ARMARiO.

The solution:

With the online control cabinet configurator, Hugo Beck now has a solution that allows the company to completely ignore the mechanical construction. The head of electrical design can carry out the entire design process completely himself. The requirements are then passed on to purchasing with all data such as item number, dimensions, design and price. A very nice solution for an electrician who needs a cabinet with special dimensions. In addition, exactly the components for defining the hole patterns in the system that Hugo Beck needs in his daily work are listed. Even if an exotic hole pattern is required, this can be created quickly and easily using the rectangle and circle functions. Simply changing from steel to stainless steel is also very convenient. A flexible system that Hugo Beck delivers results very quickly. Whenever special solutions are required, the online configurator is the preferred tool.

Long-term:

The ARMARiO control cabinet is slightly more expensive than the internal standard control cabinet, but there are no additional costs for rework. The savings are even greater for a special control cabinet, as the planning and construction costs are also eliminated. There are no experiments, no lengthy and cross-departmental dialogues and no surprises. All in all, a quick way to get completely customized housings in unique quality. With the newly developed B2B ordering process, i.e. the ability to share the created configuration with the purchasing department, it is now really perfect.

FF Maschinenbau GmbH

“Changing the account details of my cell phone contract is more complicated than configuring a control cabinet with ARMARiO.”

FF Maschinen GmbH, Pforzheim, Felix Theurer

Initial situation:

FF Maschinen GmbH is a student design office. When developing machines, the entire process is offered, from conception to product development. The focus is on the area of special machine construction, including packaging machines.

Challenge:

During development, the focus is generally on the mechanical design of the machine and only then on the electrical planning. The challenge is to first determine which controls, drives, etc. are needed. The space for the control cabinets is usually already planned, but it usually doesn't fit exactly. Often only a tailor-made control cabinet is suitable, especially because of the depth of the converters. The requirements for a control cabinet are generally not particularly high, but finding the right cutouts for switches, fans, etc. is often a challenge. In the best case scenario, these should already be finished. In the past, the drill had to be used too often and too creatively.

The solution:

The ARMARiO configurator guides you through the individual processing steps incredibly easily. A precisely fitting control cabinet could be created in just a few minutes. Components such as fans and buttons could be visually integrated, thereby creating the individual hole pattern. The visualization of the control cabinet could be downloaded and integrated into the planning of the system. In addition to the quick and easy construction, the delivery time of 10 working days was also impressive.

Long-term:

The company FF Maschinen GmbH now regularly uses the ARMARiO and enthusiastically recommends it. The different orders often require individual control cabinets. The ease of use and fast delivery make ARMARiO an indispensable partner. The fast delivery means greater flexibility can be achieved in project processing.

FiMAB STANDS FOR COMPETENCE.

IN THE PRODUCTION OF SATISFIED CUSTOMERS.

You know it too: “Yesterday we ordered 20 control cabinets in stock and then, right now, the frequency converter supplier is changing its product line and from now on the devices no longer fit in the cabinets. Just a four-figure amount for the bin stored.”

Our insider tip for you: Take new paths with us and impress your colleagues. In the co-creation process, with our control cabinet configurator, you as the user design your product exactly as you need it. Order at the right time and in the quantity you need now. Through the interactive process chain - you help shape the value creation process - and the automated interfaces, we combine the advantages of two worlds. The advantages of mass production and those of individual one-off production. Mass customization means customer-specific series production.

We at FiMAB have over 30 years of experience in the production of batch size 1 for special machine construction. From this we have developed an automated process chain from design to delivery. We produce batch size 1 in series at realistic prices. No overproduction, no storage, no waste. Such an interactive customer-supplier process makes sense not only economically, but also ecologically.

FiMAB - We will inspire you!

32 years of experience in mechanical engineering Family business in the 2nd generation More than 700 satisfied customers in Germany and Europe Over 500 customer-specific control cabinet variants delivered

CONFIGURE YOUR CONTROL CABINET ON ARMARIO NOW